Committed to supporting you and your fish farm operation’s growth, we engineer and deliver turnkey recirculating aquaculture systems (RAS). We are with you every step of the way from the initial site analysis to completion, while delivering a whole package of goods and services that are necessary for successful completion of a RAS project.

What is recirculating aquaculture systems (RAS)

RAS - a recirculating aquaculture system is a practically closed production circuit system, where more than 90% of the technological water is purified, saturated with oxygen and returned or reused continuously in production tanks.

The produced waste products (solid waste, ammonium and CO2) are removed or converted into non-harming products by the technological system. By recirculating the water, the water and energy requirements are limited to a minimum and we are not afraid to call this system a sustainable fish production solution.

Optimal conditions for fish farming

Efforts to increase production efficiency and reduce costs lead to dynamic development, especially in the field of intensive fish farming, which in many cases is based on water recycling. Recirculation units are able to provide optimal conditions for fish farming, both in terms of water quality and feed supply with low water consumption. The water used in the recirculation unit is purified and, thus, does not affect the physic-chemical composition of the water under the unit (recipient).

The operation of the recirculation unit does not depend on changing natural and climatic conditions. A closed recycling system for intensive fish farming is based on the minimum water consumption that must be supplied to the system to compensate for losses due to evaporation. The functional efficiency of the system is determined by efficient water purification.

RAS main advantages

- Stable production of high quality fish, 365 days a year

- Low water requirement

- High production of quality fish on a relatively small area

- Reduced risk of diseases

- Low mortality rates

- Continuous control

- No environmental influences

- Intake and effluent reducing to the minimum

- Treatment of discharge water

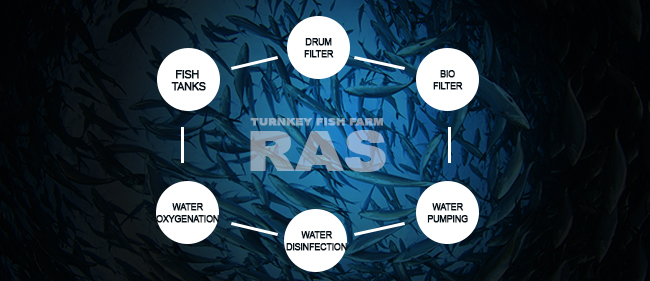

Recirculating aquaculture systems components

All RAS systems constructed by our company have the following components:

- Pumps

- Bio-filters

- Solids collection systems (a rotating drum filter)

- A foam fractionation unit (also known as a protein skimmer or dissolved air floatation device)

- Carbon dioxide degasser

- Nitrate filter

- Sterilisation points (usually UV sterilisation)

- Tank drainage system that separates wastes from main outflows

- Temperature control (heat pump or evaporative cooling)

- Heat exchange of effluent waters

- Oxygen injection system

- A pH control and alkalinity dosing system

RAS water quality & quantity

The required water quality is maintained by double filtration, where purification takes place first in the drum filter, which captures mechanical impurities followed by biofilter with microorganisms, requiring sufficient air volume. Water quality is also supported by disinfection with ozonizers and germicidal lamps with UV radiation. The water treated in this way is heated or cooled in a storage tank to a temperature that meets the temperature requirements for a particular type of fish.

But only after oxygenation can water be used in pools with fish. All water in the unit is constantly circulating, continuously cleaned and oxidised. To avoid circulation and purification interrupt, it is necessary to have a backup power source for the event of a power failure. If this is not taken care of, in case of a power outage, fish stocks of the facility will become subject to death. The size of the fish stock in the pools is determined by the ratio of the fish weight to the amount of water in the pool.